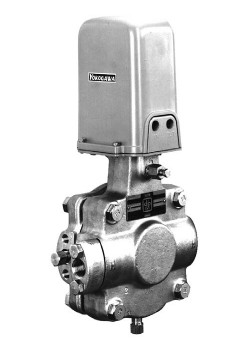

YOKOGAWA Y/11AL Pneumatic Absolute Pressure Transmitter

Model Y/11AL Pneumatic Absolute Pressure Transmitter measures absolute pressure in spans from 1.3 to 5.3 kPa.

The instrument transmits a proportional 20 to 100 kPa pneumatic signal to remote pneumatic receivers.

Ordering Examples:

Y/11AL-LS1

Y/11AL-LS2

Y/11AL-LS3

Y/11AL-LS4

If you do not have complete model number, never mind, just supply us detailed parameters by email, we can choose model number and give you a quotation immediately.

■FEATURES

● Time-Proven Pneumatic Differential Pressure

Transmitter Design

● Trouble-Free Construction.

● Excellent Performance.

● Easy to Calibrate.

● Wide Range.

● Overrange Protection.

● Stable Absolute Reference.

■STANDARD SPECIFICATIONS

Span Limits:

1.3 to 5.3 kPa.

Span is continuously adjustable within range limits.

Range Limits:

0 to 9.3 kPa absolute.

Overpressure Limits:

0.7 MPa.

Output Signal:

20 to 100 kPa.

Accuracy (includes linearity, hysteresis and

repeatability):

_1.0 % of span.

Repeatability:

0.5 % of span.

Dead Band:

0.1 % of span.

Air Supply Pressure:

140 kPa, 1.4 kgf/cm2 or bar, or 20 psi.

Air Consumption:

0.5 m3/h at 0 _C, 101.3 kPa {1.033 kgf/cm2} absolute (0.3 scfm).

Ambient Operating Temperature Range:

-40 to 120 _C (-40 to 250 _F).

Process Temperature Limits:

-40 and 120 _C (-40 and 250 _F) at capsule.

Mounting:

Bracket for nominal 50 mm (2 inches) horizontal or vertical pipe. Transmitter must be mounted with capsule faces vertical.

Air Connection:

Tapped for JIS R1/4 or 1/4 NPT, whichever specified.

Model Y/11AL Pneumatic Absolute Pressure Transmitter

Yokogawa Electric Corporation

Process Connection:

JIS Rc1/2, Rc1/4, 1/2 NPT, or 1/4 NPT female, whichever

specified.

Wetted Parts Material:

Body: Forged JIS SUS 316 stainless steel.

Process Connector: SCS 14A (equivalent to SUS 316 Stainless Steel casting)

Diaphragm Capsule: SUS 316L stainless steel.

Force Bar: SUS 316 stainless steel.

Force Bar Seal: Cobalt-nickel alloy.

Process Connector Gasket: Teflon (PTFE) (see Note 1).

Capsule Gasket: SUS 316L stainless steel coated with Teflon.

Force Bar Seal Gasket: Silicone elastomer.

Connection Hardware:

JIS SCM 435 chrome-molybdenum steel cap screws and nuts for body; JIS SCM435 cap screws for process connector.

Cover:

Cast aluminum, finished with gray polyurethane paint.

Gasketed for National Electrical Manufacturers Association (NEMA) (USA) Type3 weatherproof service.

Approximate Weight:

15 kg (33 lb).